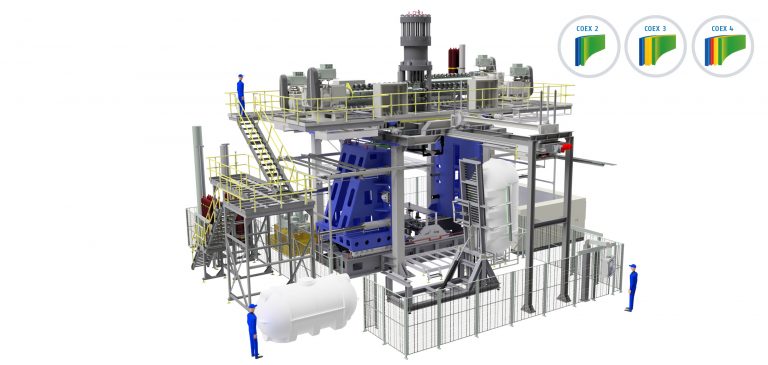

RIKUTEC GBM S4000 – S6000

HIGH PERFORMANCE MULTI-LAYER COEXTRUSION BLOW MOLDING MACHINE

With this machine type, the world’s largest multi-layer blow molding part was achieved. A blow-volume of up to 10,000 l, accumulator head up to 400 l as well as closing forces of up to 600 t are availible.

CLAMPING UNIT

Both mold platens are guided by 4 runner blocks with a linear guiderails system on a closed frame. The closing and opening motions of the mold platens are done hydraulically with proportional valves, controlled via digital sensors and the machine control. The movement of each plate is controlled separately, which allows synchronous or asynchronous movements.

COEX AND BI-EX ACCU-HEADS FROM 150 UP TO 400 LITERS

ACCU-HEAD

The RIKUTEC Coextrusion Accumulator Head works to the „first in /first out“ system. The hydraulically driven injection piston is controlled by means of a proportional valve (speed control). The piston for controlling the wall thickness is controlled by means of a separate circuit including a control valve.

Upon product requirement different systems for partial wallthickness control can be offered.

EXTRUDER

Extruder with grooved and cooled infeed bushing and barrier screw with mixing tip. For processing HMW-HDPE as powder or pellets.